Dual throttle body installation instructions

Make sure you read all of Holleys instructions as well as ours, and the video links to help your installation go as easy as possible!

When you install, follow ALL of Holleys instructions EXCEPT do not run the startup wizard, and do not touch the idle speed adjustment screw. We have already pre-load the 13.5:1 idle tune into the ECU!

Here is a detailed installation video we made:

There are changes since this video regarding the fuel system!

If you have purchased our fuel system rather than the Holley fuel system that we used to use the install for that is now different!

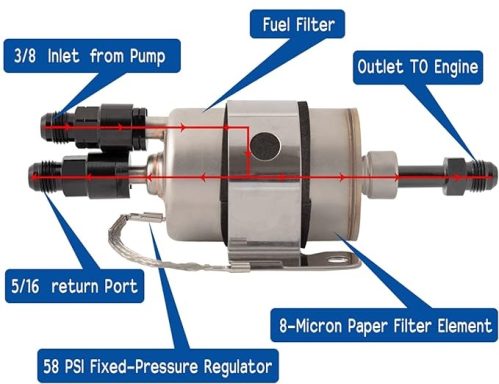

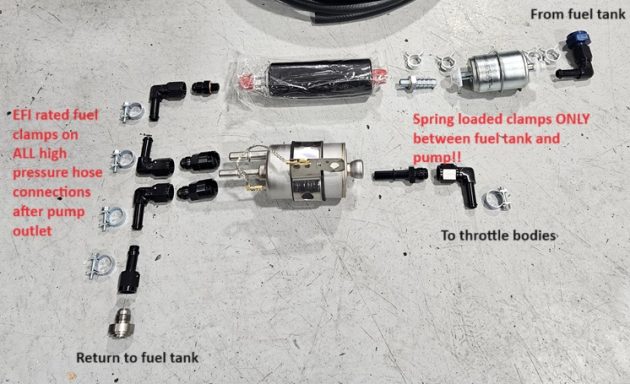

With our new fuel system we only run a single fuel line to the back of the car. This simplifies installation and reduces cost of the extra high pressure fuel line. The new system utilizes the GM LS style fuel pressure regulator/filter. We still only recommend a dedicated return line to the bottom of the fuel tank. We do not recommend using a "Tee" on the bottom of the fuel tank for the return and feed. Although it is a lot easier than welding the included 6AN bung into the bottom of the tank we have seen the constant recirculation of the fuel cause pumps to overheat and loose fuel pressure. The new fuel system puts the entire fuel loop under the fuel tank opposite the brake master cylinder. Using the included 90 degree 6AN fittings you can assemble the pump and filter/regulator into a compact assembly sharing a single bolt to secure it to the floor pan area. Included is the WIX pre-filter as well. Clearance from the fuel outlet with a 90 degree fitting can be tight fitting to the chassis tunnel. We recommend installing the fuel outlet then reinstalling the tank. Install the fuel return on the bottom of the tank in a location that will not interfere with the steering column or the tie rods, etc. The low spot closest to the front bulkhead serves as an easy location to install. On a bus we locate it on the lower left side of the fuel tank near the bottom. On Bay window tanks we have drilled a hole in the panel covering the fuel tank for the fuel line to pass through to the tank for its return.

On our installations we run the supplied 3/8" fuel line down the passenger side of the pan, up in the channel that the body to pan bolts reside. We have found if you straighten out a 1/2" conduit clamp and zip screw it to the outer edge of the pan it holds the fuel line up in place (along with the fuel pump wire and CAN extension cable) very nicely and keeps it up above the bottom of the chassis away from harm.

With the single fuel line going into the throttle bodies, use the supplied 6AN cap to cap off the last fitting on the fuel rail, the supplied 90 degree sweeps will be used to connect the fuel lines through both fuel rails.

The “Coolant” temperature sensor needs to be installed where it will get a good temperature reference from the cylinder heads. DO NOT install the temp sensor into the oil system or the engine case. These temperatures are too slow and not representative of the chamber temperature to dictate how much warmup enrichment the system should provide. We prefer to install the sensor on the left side through the engine tin to pick up heat coming off the heads and cylinders. If you like a clean engine bay, or have an open engine bay like a baja, trike, etc, a sensor is available at TheDubShop.com (part # SEN_CLT_MOD) that can attach under the cylinder head tin screws, or the stock EFI temp sensor location for the later models that had injection.

Once you have the system installed, jump the relay to run the fuel pump and check for fuel leaks. The throttle bodies will need to be setup like dual carbs will. A good starting point is to turn both throttle adjustment screws in 2 turns from zero. Set your throttle linkage up like you would dual carburetors so you can fire it up. It will ask you to do a TPS calibration before you can run the car. Follow the prompts for that. Once calibrated, fire up the car.

We load the handheld SD card with three tunes. All are identical except the idle mixture. Once the engine runs it will need to get up to temperature for the system to start to adjust itself. First the Closed Loop will activate, this is the more instant fuel correction, while the Learn won’t kick in until the engine is warmed up. This is a much slower correction so that it performs more of an average of what is needed for consistency. Both will only work during steady conditions so don’t be alarmed if it goes in and out.

Here is a video that shows how the closed loop and the "Learn" work so you have a better understanding of how the system works. It may run rough before it starts doing fuel correction but once that kicks in it will start responding and cleaning up the tune really quick.

https://www.youtube.com/watch?v=Su1aTpDh8iY

This video shows how to change the tunes where we offer three different idle air/fuel ratios. 12.5, 13.5, and 14.5. I start it out with the 13.5 one which is most common, some engines like it, and all most will run on it. With it fully warmed up, try each one and see which one settles that gives you the lowest IAC (Idle Air Control) percentage on the screen when fully warmed up. The lower the percentage, the more it likes it. This is the alternative to basically a lean drop on a carb adjustment.

https://www.youtube.com/watch?v=J_61F1pRq9c

While the system first learns and adapts to your engine you may run out of learn percentage. General rule for me is anytime I see greater than 20% "Learn" show up on the screen at all it's a good idea to transfer the fuel table. When you go to "Transfer Table" select “RUN” but when it asks if you want to smooth the fuel table select “Cancel”. It still transfers the table but it doesn't smooth the whole fuel map out. On some engines we have found the smoothing of the table takes away some of the learn from other areas. It's not a big deal if you select Yes, but it will work on relearning those areas it smoothed that is didn't need to. Bad wording on Holleys part to say "cancel", it makes it sound like you are not transfering the learn table, but you are.

If on initial startup the air/fuel ratio reads extremely rich, or extremely lean and won’t run long enough to get the system to start correcting, please let us know what the air/fuel values are showing and we can re-send your tune through email to load on the SD card with the fuel map either richened up, or leaned out to help you get tuning sooner.

Once running and best idle mixture chosen, dial in the throttle bodies like you would carburetors. If you have Idle Air Control (IAC) on your system, what we like to do is set the idle speed in the handheld down to 600rpm so it is effectively “off” and set the idle speed where it sounds best. Once that’s set and it’s idling good, note the idle rpm and go back into the handheld and set that as your idle speed. This will allow the IAC to be fully utilized for helping maintain cold idle, and maintain the target idle speed.

Any questions that aren't covered in those video's, let me know

Thanks again,

Eric Allred

Red-E Motorsport

Installation pictures

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.